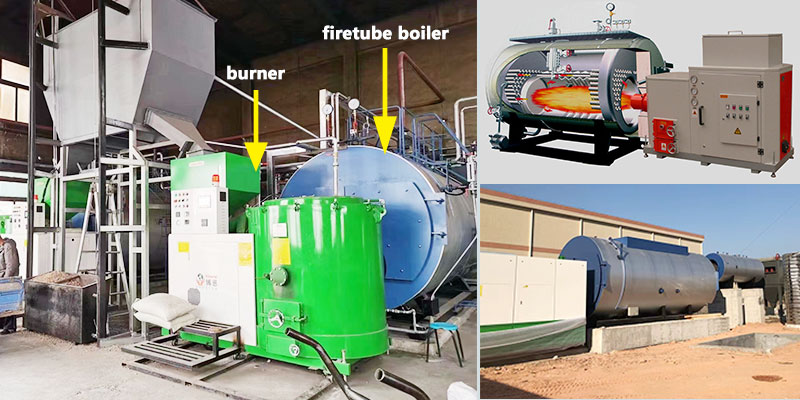

Gas/diesel fire tube boiler, Wood biomass fire tube boiler

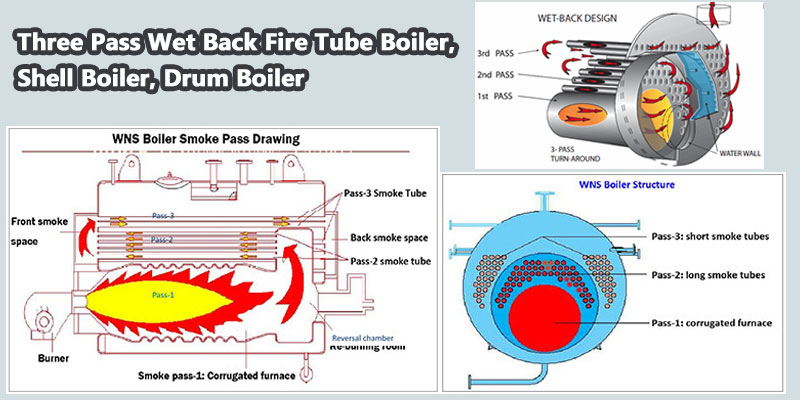

Fire tube boiler is an 3-pass industrial boiler composed of multiple groups smoke tubes, drum, front and rear tube plates, corrugated furnace, and reversal chamber etc. It can be equipped with fueloil/gas burner or biomass burner. Also called shell boilers or drum boilers, used to generate steam or hot water for production process.

| Output: | Steam, Hot-water |

| Capacity: | 0.2ton-40ton, 200kg-40.000kg, 120kw-28.000kw |

| Pressure: | 0-3.8Mpa, 0-38bar |

| Layout: | Horizontal, Vertical, Containerised |

| Applied fuel: | Natural gas, lpg, biogas, diesel, heavy oil, dual fuel, biomass pellet, wood chips, sawdust etc |

Please enter your email address below

Fire Tube Boiler Structure

Fire tube Boiler is an industrial boiler composed of multiple groups smoke tubes, drum, front and rear tube plates, corrugated furnace, and reversal chamber etc. It can be equipped with fueloil/gas burner or biomass burner. Also called shell boilers or drum boilers, used to generate steam or hot water for production process.

It is a must-have machine in a wide range of fields like food, beverage, paper, textile, feed mill, pharm, wood, package, chemical, building materials, laundry...

With more than 60 years of experience in industrial boiler, YUANDA BOILER has specially developed 3 hot types of fire tube boilers: WNS horizontal series, LHS vertical series, WNS-T biomass fire tube boiler series.

It adopts horizontal three-pass wet-back structure, large corugated furmace and thread smoke tube technology, 5-th water level protection, equipped wih intemational first-level brand burners and valves, instruments,advanced expansion welding technique, and independently developed high-matching PLC control system to realize muitiple linkages, protects the equipment long uselife & running safely.

WNS-T is the fire tube boiler fired by biomass/wood fuel, equipped with biomass burner.The fan in the burner blow the flame and high temperature exhausted gas into boiler furnace, then flow through spirally corrugated fire tubes, front smoke chamber and rear smoke chamber, into dust collector and chimney.

It adopts vertical fire tube structure, small in size, space-saving, occupies less footprint; no need to build boiler room, reduce cost and high flexibility; Simple structure, fast start and stop; lower thermal efficiency than horizontal boiler.

YUANDA BOILER is a high-quality industrial boilers manufacturer integrating R&D, production, sales, and service. The fire tube boiler machine have the following advantages:

Anti-dry heating system with five stages water level check;

Four stages pressure protection;

Explosion-proof door with fire viewer;

Remote monitoring system.

Large radiate heating surface corrugated furnacePatent design spirally smoke tubes;

Double 12mm thickness aluminum silic ate insulation layer

Finned tube design economizer with aluminum silicate insulation, greatly reducing heat loss

Wet-back smoke conversion chamber;

Solid round steel tension rod design;

Rapid solidification and high-strength refractory building materials;

Double opening-door at front and back.

Easy for transportation and installation, also could be pre-installed in the factory, customers only need to connect water, electricity, fuel, etc.

Henan Yuanda Boiler Corporation Ltd., founded in 1956.

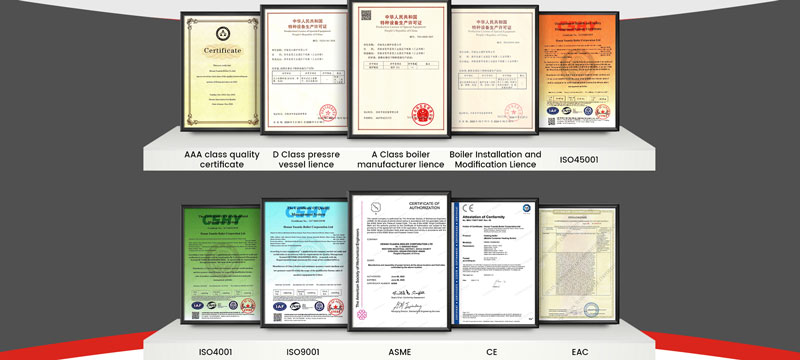

Passed ASME CE ISO EAC DOSH TUV BV SGS certification, boiler projects covered more than 132 countries.

■ Established in 1956, as a stated owned enterprise.

■ Over 16 years export experiences, payment & shipping protection

■ CE ASME DOSH EAC GOST ISO high standard boiler certified

■ Production of various types boilers, provide pre-sale boiler proposal for customer select

■ Directly factory low price & quality protection.

■ Completed technology & after-sale service team.

■ Support Video/VR inspection. Abroad installation and commissing service etc

■ Technical discussion, drawing about boiler solution for your company use

Service:

Pre-sale Service:

1. Design一We help customer to choose the best boiler model according to the different requirements of different industries.

2. Drawing and files一Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution一Design completed boiler solution with installation materials for your company.

4. Transportation一We have shipping partners and forwarder for lowest price and safe.

After-sale Service:

1. Provide a full range of boiler and original spare parts.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.

One-stop Boiler Solution

Please feel free to send all your inquiries or production needs, so we can provide professional boiler solution for you.

Parameter

| Model | Horsepower | Rated steam output | Rated pressure | Rated temperature | Feed water temperature | Fuel consumption | |

| (hp) | (Ton/hr) | (Mpa) | (℃) | (℃) | Light diesel oil(kg/h) | Natural gas(Nm3/h) | |

| LSS0.1 | 7hp | 0.1 | 0.4/0.7 mpa | 130~171 | 20/105 | 6.7 | 7.3 |

| LSS0.2 | 15hp | 0.2 | 130~171 | 20/105 | 12.8 | 17 | |

| LSS0.3 | 25hp | 0.3 | 130~171 | 20/105 | 19.2 | 25.5 | |

| LHS0.5/LSS0.5/WNS0.5 | 35hp | 0.5 | 130~171 | 20/105 | 32 | 42.5 | |

| LHS0.7/WNS0.7 | 50hp | 0.7 | 130~171 | 20/105 | 49.5 | 51 | |

| LHS1/WNS1 | 65hp | 1.0 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0 mpa | 130~185 | 20/105 | 70 | 80 |

| LHS1.5/WNS1.5 | 100hp | 1.5 | 130~185 | 20/105 | 108.7 | 115.4 | |

| LHS2/WNS2 | 125hp | 2 | 130~185 | 20/105 | 135.2 | 150.4 | |

| WNS3 | 200hp | 3 | 130~226 | 20/105 | 192.9 | 212.1 | |

| WNS4 | 250hp | 4 | 130~226 | 20/105 | 258.2 | 283.4 | |

| WNS5 | 300hp | 5 | 130~226 | 20/105 | 323.5 | 354.7 | |

| WNS6 | 350hp | 6 | 130~226 | 20/105 | 388.6 | 424.2 | |

| WNS8 | 500hp | 8 | 130~226 | 20/105 | 514.6 | 566.3 | |

| WNS10 | 600hp | 10 | 130~226 | 20/105 | 641.7 | 707.8 | |

| WNS12 | 720hp | 12 | 130~226 | 20/105 | 768.9 | 849.3 | |

| WNS15 | 900hp | 15 | 130~226 | 20/105 | 960.1 | 1061.7 | |

| WNS20 | 1200hp | 20 | 130~226 | 20/105 | 1276.2 | 1415.8 | |

Relate Cases

Recommend Boiler

Oil Gas Fire Tube Boiler

Horizontal oil gas fired fire tube boiler, Fully automatic, 3-pass wet back design

Verticla Fire Tube Boiler

Vertical oil gas fired fire tube boiler, Small footprint, low cost, quick into use

Biomass Fire Tube Boiler

WNS biomass fire tube boiler, can convert gas/oil to biomass, biomass to gas/oil fuel

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler