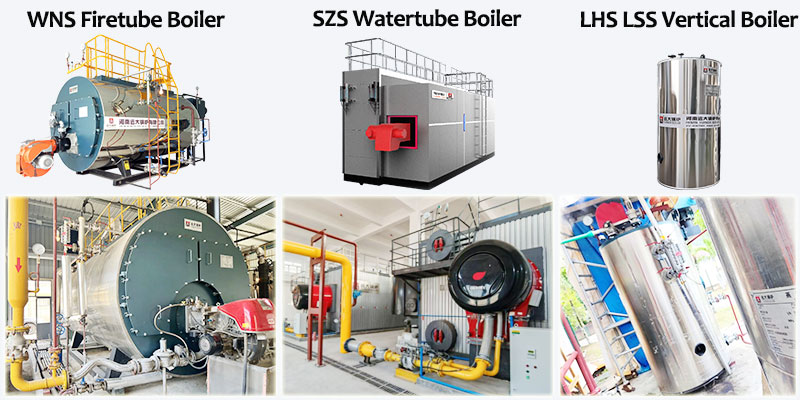

Fire tube boiler| Steam generator boiler | Hot water heater boiler

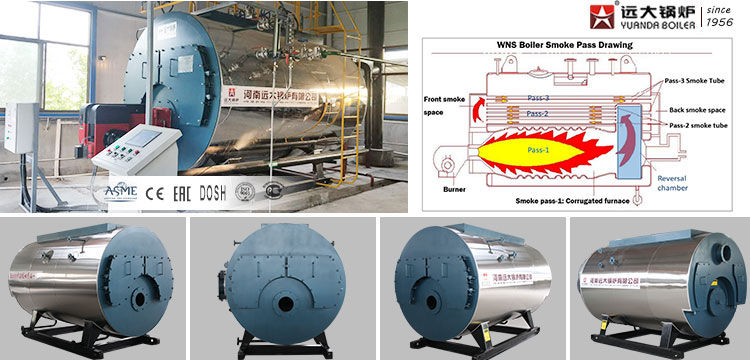

WNS oil/gas fired boiler is the Automatic Horizontal Fire Tube Boiler. Adopts three pass wet-back structure, larger corugated furmace, thread smoke tube with unique expansion welding technique. Equipped with international first-level brand burners, strong output, 25 years lifetime.

| Output: | Steam, Hot-water |

| Capacity: | 0.1ton-40ton, 100kg-40000kg, 99kw-28000kw |

| Work Pressure: | 3-38bar, 0.3-3.8Mpa |

| Heat Temperature: | 0-450℃ |

| Applied Industry: | Food, Beverage, Feed, Textile, Paper, Chemical, Package, Refinery, Pharm, Building Material, Hotel... |

Introduction

Natural Gas/Diesel/LPG/Biogas/Bunker/Dual Fuel Boiler

Yuanda Boiler aim to offer efficient and energy-saving gas/oil fired boilers to provide steam or hot water for factory production.

It is favored by users for its thermal efficiency >98.8%, high quality and environmental protection.

WNS gas/oil boiler adopts horizontal fire tube structure, which can provide larger steam/water output. It has the following advantages:

* 3-pass wet back reverse flame chamber;

* Fuel saving with economizer;

* Larger "steam-water" space with steam separator, high steam quality;

* Packaged boiler design, easy installation;

* Automated operation by PLC and safety functions such as water level, pressure and temperature monitoring;

* Equipped with international first-class brands burners and valves.

LHS vertical gas/oil fired boiler have smaller capacity (0.1-2ton,100-2000kg,99-1400kw), a kind of fast-heating packaged boiler.

It adopts up-standing vertical structure, small in size, space-saving, occupies less footprint; no need to build boiler room, reduce cost and high flexibility; Simple structure, fast start and stop; lower thermal efficiency than horizontal boiler.

▲ High Efficiency, Save Fuel & Running Cost

Large radiate heating surface corrugated furnace, Patent design spirally smoke tubes;

Double 12mm thickness aluminum silic ate insulation layer

Finned tube design economizer with aluminum silicate insulation, greatly reducing heat loss

▲ High Security, Safe Operation

Anti-dry heating system with five stages water level check;

Four stages pressure protection;

Explosion-proof door with fire viewer;

Remote monitoring system.

▲ Long Lifetime and Convenient Maintenance

Wet-back smoke conversion chamber;

Solid round steel tension rod design;

Rapid solidification and high-strength refractory building materials;

Double opening-door at front and back.

▲ Easy to Install, Lower Installation Cost

Packaged type boiler, easy to transportation and installation.

Can be pre-installed in factory, only connect water, electricity, fuel at site

■ Founded in 1956, quality supplier inspected by SGS Group

■ CE ISO quality certified

■ More than 17 years of export experience, gold medal supplier, guaranteed payment and delivery

■ Integrating research&development production and sales

■ Support video/VR or third party factory inspection

■ Exported to 108 countries, more than 100,000 customers

Quality Control Method

Steel element test→Steel rust cleaning→Welding electrodes drying process→Automatic welding, argon arc welding, expansion welding etc. methods→NDT(Nondestructive Testing) including X-ray Test, Ultrasonic Test, Magnetic particle Test→Hydraulic pressure test.

Our Service

Pre-sale Service:

1. Design一We help customer to choose the best boiler model according to the different requirements of different industries.

After-sale Service:

1. Provide a full range of boiler and original spare parts.

2. Drawing and files一Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution一Design completed boiler solution with installation materials for your company.

4. Transportation一We have shipping partners and forwarder for lowest price and safe.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.

Parameter

| Model |

Capacity (Ton/h) |

Horspower (hp) |

Pressure (Mpa) |

steam temperature (℃) |

Feed water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | ||||||

| WNS 0.5 | 0.5 | 35 | 0.4 to 3.82mpa | 130~450 | 20/105 | 32.5 | 35.7 |

| WNS 1 | 1 | 71 | 0.4 to 3.82mpa | 130~450 | 20/105 | 64.6 | 70.1 |

| WNS1.5 | 1.5 | 120 | 0.4 to 3.82mpa | 130~450 | 20/105 | 96.8 | 105.2 |

| WNS 2 | 2 | 150 | 0.4 to 3.82mpa | 130~450 | 20/105 | 129.3 | 140.3 |

| WNS 3 | 3 | 200 | 0.4 to 3.82mpa | 130~450 | 20/105 | 192.9 | 212.1 |

| WNS 4 | 4 | 300 | 0.4 to 3.82mpa | 130~450 | 20/105 | 258.2 | 283.4 |

| WNS 5 | 5 | 350 | 0.4 to 3.82mpa | 130~450 | 20/105 | 323.5 | 354.7 |

| WNS 6 | 6 | 425 | 0.4 to 3.82mpa | 130~450 | 20/105 | 388.6 | 424.2 |

| WNS 8 | 8 | 550 | 0.4 to 3.82mpa | 130~450 | 20/105 | 514.6 | 566.3 |

| WNS 10 | 10 | 700 | 0.4 to 3.82mpa | 130~450 | 20/105 | 641.7 | 707.8 |

| WNS 12 | 12 | 850 | 0.4 to 3.82mpa | 130~450 | 20/105 | 768.9 | 849.3 |

| WNS 15 | 15 | 1050 | 0.4 to 3.82mpa | 130~450 | 20/105 | 960.1 | 1061.7 |

| WNS 20 | 20 | 1400 | 0.4 to 3.82mpa | 130~450 | 20/105 | 1276.2 | 1415.8 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | |||||||

| Model |

Rated heating capacity (mw) |

Rated working pressure (Mpa) |

Output water temperature (℃) |

Return water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | |||||

| WNS 0.35 | 0.35mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 31.6 | 36.6 |

| WNS 0.7 | 0.7mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 60.4 | 69.3 |

| WNS 1.4 | 1.4mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 122.8 | 146.1 |

| WNS 2.1 | 2.1mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 192.3 | 227.1 |

| WNS 2.8 | 2.8mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 246.1 | 286.5 |

| WNS 4.2 | 4.2mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 367.1 | 412.6 |

| WNS 5.6 | 5.6mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 490.2 | 543.7 |

| WNS 7.0 | 7.0mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 593.6 | 660.7 |

| WNS 10.5 | 10.5mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 936.5 | 998.8 |

| WNS 14 | 14mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 1200.8 | 1330.7 |

| Note: for place limited, we didn't list all models, if you need other capacity, pressure, fuel, please send us inquiry directly, we will send you detailed parameter. | ||||||

Relate Cases

Recommend Boiler

Skid-mounted Boiler

Skid-mounted steam boiler and hot water boiler systems represents an all-in-one, ready-to-operate boiler solution.

Vertical Oil / Gas Boiler

More suitable for: small space, low budget, OR steam demand of 100 to 2000 kg/h, 120 to 1400 kw/h

SZS Water Tube Boiler

SZS water tube packaged gas/oil boiler, larger furnace with light membrane wall, high efficiency

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Products Series

Contact Supplier