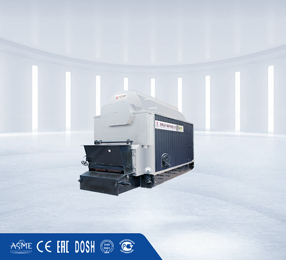

SZW biomass boiler | Step grate biomass boiler | Water tube boiler

SZW reciprocating grate boiler is also named as step grate boiler. Compared with other types of boilers, reciprocating grate biomass boilers are more suitable for burning biomass fuels with high moisture and low calorific value. Of course, this kind of boiler has a larger steam separation area, provides high-quality steam, larger steam storage capacity, etc.

| Output: | steam/hot water |

| Capacity: | 4 ton/h-50 ton/h |

| Horsepower | 250hp to 2500hp |

| Available Fuel: | briquettes, wood waste, empty fiber bunches,rice husk, bagasse, palm kennel, forest waste |

| Applied Industries: | sugar, chemical, paper, textile, food, pharmaceuticals, heating industry and construction industry, etc |

Introduction

We offer both compact and semi-assembled reciprocating grate boiler, whose benefits include fuel flexibility, low maintenance, easy start and stop, high efficiency, high availability, and reliability.

Key Highlights of SZW Biomass Boiler

Capacity range 4 – 60 TPH, Pressure Up to 40 bar pressure

Tube & tile / Full Membrane wall furnace

Saturated / Superheated steam (up to 450˚C)

Multiple Biomass fuel options are available

Fuel’s with High Moisture upto 55 – 60% can be fired

Replacement of grate Bar is very easy

Resistance in High Temp and low wear & tear

pares are easily available is in house and are economical

Core Technology

The grate speed and angle can be adjusted according to different fuels to ensure complete combustion. It is divided into drying zone, burning zone, post-burning zone and ash zone.

The bottom of the feeding device has a rotatable adjusting plate, where has seeding wind. When changing the angle between adjustment plate and horizontal plane, the dropping point on the grate can be adjusted.

Three sets of secondary air are set on the furnace.

The pitch of convection heating surface is in-line arrangement.

Advantages

1. Increase the combustion share of middle furnace, reduce the overall temperature of the furnace.9. Biomass fuel is apt to slagging, the convection bank has acoustic wave soot blower, which may remove the soot, and cleaning door is equipped.

10. Both air cooled and water cooled grate designs available, depending on the cooling method selected as per the fuel characteristics

About Yuanda Boiler

■ Established in 1956, as a stated owned enterprise.

■ Over 16 years export experiences, payment & shipping protection

■ CE ASME DOSH EAC GOST ISO high standard boiler certified

■ Production of various types boilers, provide pre-sale boiler proposal for customer select

■ Directly factory low price & quality protection.

■ Completed technology & after-sale service team.

■ Support Video / VR factory-inspection. Abroad installation and commissing service etc

■ Technical discussion, drawing about boiler solution for your company use

Service

WELCOME Contact Us for Boiler Information

Just please confirm 4 points as bellow, we will offer the appropriate boiler model for you, with price, specifications, running pictures.

1. How many ton/kg/kw/hp/kcal capacity you need?

2. What pressure or temperature you need?

3. What fuel you plan to use?

4. What factory will you use the boiler?

Parameter

Relate Cases

Recommend Boiler

DZL Coal boiler

Single drum chain grate burning solid fuel boiler, water&fire tube boiler, fully automatic

WNS Oil Gas Fired Boiler

Horizontal 3-pass fire tube boiler with famous burner. Energy saving

DZH Coal/Wood Boiler

Traveling grate boiler, hand-feed, running stable, suitable for bigger solid fuel

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Products Series

Contact Supplier