Medical, Hospital, Infectious, Plastic, General waste

CE FDA approved, up to standard discharge, smokeless and odorless. Suitable for hospital waste, infectious waste, sharps, pharmaceutical and pathological waste, biowaste, plastic waste, public waste, industrial waste, etc

| Model: | YDF |

| Capacity: | 20kg, 30kg, 50kg, 100kg, 150kg, 200kg, 300kg, 400kg, 500kg, 750kg |

| Type: | Manual, Automatic, Mobiled |

| Fuel: | Gas, Diesel |

| Application: | Solid waste, medical waste, industrial waste, general garbage, animal carcass, and other special waste |

Introduction

YDF Waste Incinerator is an ideal waste treatment machine for solid waste, such as hospital waste, infectious waste, sharps, drugs, pathological waste, animal carcass, plastic waste, public waste, industrial waste, etc

Also known as double chamber incinerator, combustion temperature can reach over 1300°C. And controlled by control panel, which is easy to install and operate.

Customized designs are available based on waste type. It has incinerator with venturi dust remove, automatic incinerator, front-loading and top-loading incinerator for choose.

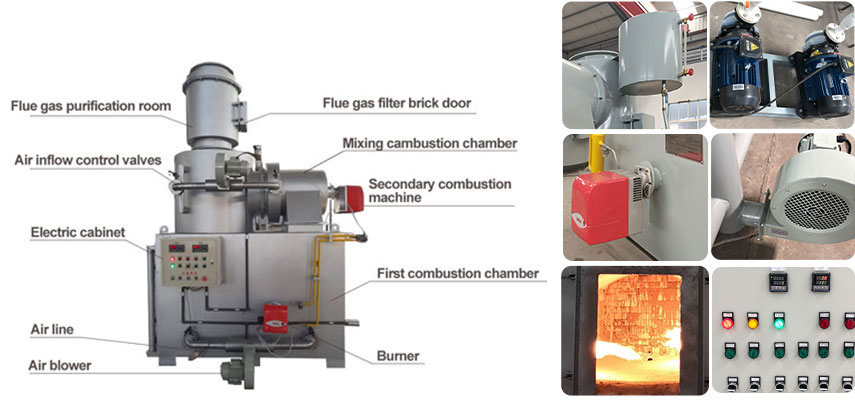

Mainly 4 parts: First combustion chamber, Second re-burning combustion chamber, Then flue gas purification chamber, and Electric control panel.

It represents the advanced incineration method, from pyrolysis and gasification in the primary combustion chamber, to burnout in the secondary reburning chamber, then to the flue gas purification chamber, and finally into the chimney.

▲Smokeless and Odorless, Low Emission Standards

①High-temperature pyrolysis gasification technology+mixed incineration+burnout treatment;

②Single/double/multi-stage flue gas treatment;

③Enclosed burning, avoid secondary pollution;

④The chamber temperature up to 1300°C, retention 2 seconds;

▲High Burning Rate, Save Fuel Cost

①Double chamber for incineration;

②With first-class Itlay burner brand, fully output;

③Primary combustion chamber automatically starts and stops, effectively utilizing high-temperature flue gas, save fuel.

▲Long Life Time, Easy Operation

①Front opening to facilitate loading and easy collect slags;

②Pre-assembled and well-debugged before delivery;

③Use ceramic fiber sealing tape rather than asbestos material. And high-strength refractory materials;

④Auto ignition, auto control and temperature monitoring, automatic power cut off

■ Founded in 1956, quality supplier inspected by SGS Group

■ CE ISO quality certified

■ More than 17 years of export experience, gold medal supplier, guaranteed payment and delivery

■ Integrating research&development production and sales

■ Support video/VR or third party factory inspection

■ Exported to 108 countries, more than 100,000 customers

Quality Control Method

Our Service

Pre-sale Service:

1. Incinerator model recommendation, budget analysis

2. Layout drawings, quality certificate, factory inspection

3. Fuel/electricity consumption and cost analysis

4. Factory directly manufacture, high quality and low price

After-sale Service:

1. Provide a full set of incinerator and original spare parts

2. Teaching video, training service

3. 24 hours online, quick respond for any questions

4. Free maintenance and repair for one year and lifetime service.

Parameter

| Model | YDF-20 | YDF-30 | YDF-50 | YDF-100 | YDF-150 | YDF-300 | YDF-500 |

|

Burning Capacity (5-6 batch/day) |

20-30kg/h | 20-30 kg/h | 30-50 kg/h | 50-100 kg/h | 100-150 kg/h | 200-300 kg/h | 300-500 kg/h |

| Incinerator Size(m) (L*H*B) | 1.6*1.3*1.75 | 1.45*0.9*2.55 | 1.8*1.15*3 | 1.8*1.4*3.4 | 2*1.4*3.5 | 2.2*1.4*3.8 | 3*2*4.8 |

| Imputing Size(mm) | 380*480 | 480*600 | 620*800 | 760*960 | 760*960 | 900*1100 | 1080*1280 |

| Chimney External Diameter(mm) | 280 | 280 | 280 | 300 | 300 | 400 | 460 |

| Draught Fan | 0.25kw | 0.37kw | 0.37kw | 0.5kw | 0.5kw | 1.1kw | 1.1kw |

| Voltage |

380V 220V |

380V 220V |

380V 220V |

380V 220V |

380V 220V |

380V 220V |

380V 220V |

| Weight(kg) | 1800 | 3000 | 5000 | 7000 | 8200 | 10000 | 16000 |

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Products Series

hospital incinerator

medical incinerator

pet incinerator

animal incinerator

container incinerator

Contact Supplier