CFB boiler | solid fuels boiler | Power generation boiler

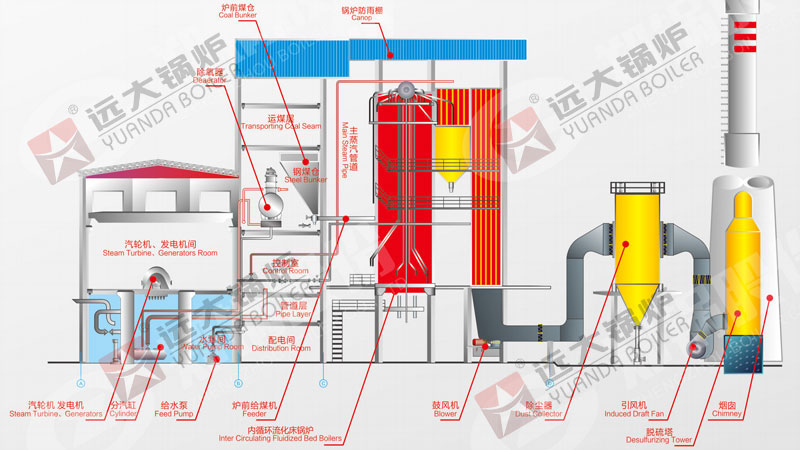

YD-CFB boiler is an advanced circulating fluidized bed boiler developed by Yuanda Boiler. It can efficiently use nearly all solid fuels from biomass to alternative fuels and waste, to produce steam and electricity while minimizing emissions of nitrogen oxides and sulfur oxides.

| Output: | steam or hot water |

| Capacity: | 4ton-70ton, 2.8mw-49mw |

| Fuel: | coal, biomass, waste, solid fuel |

| Pressure: | 0-3.8Mpa, 0-38bar |

| Used for: | steam, hot water, geenrating electricity |

Introduction

YD-CFB boiler is an advanced circulating fluidized bed boiler developed by Yuanda Boiler. It can efficiently use nearly all solid fuels (from biomass, wood to RDF, alternative fuels and other solid waste) to produce steam and electricity while minimizing emissions of nitrogen oxides and sulfur oxides.

1. What makes the structure stable is the adoption of membrane wallby the whipool trpe separcator of ths produt,forming the sleleton of separctor, so thetthe separation efficiency is high The separator is also arfulM lid info integration with the combustion chamber and the soot boack feeding system, maingthe boiler structure compact.

2. The back feeding system adopts the patent technology of membrane water cooing woall and the oop-bock deice of semiselHfow ,muli-hole andmembrane type, so that the back feeding can be even.

3 The oapplication of low temperature combustion technology can effectively reduce the generation of hazardus gas and the emission of NOx.

4. The application of energy-saving low speed fhuidization design, muli-grade high temperature separation,inner furmace twice puriied separation,new type wear-resistarnt material, etc., effectively guarantee the improvement of abrasion resistance of different components.

5. Very low failure rate, can be continuously operated for a long time, the maximum operation period can be as long as 300 days.

Highest fuel flexibility to burn coal/biomass fuels, even low grade solid fuel or multi-fuel combustion

Environmentally-friendly. Almost complete combustion with low emissions(1. Low CO, TOC emissions,2. Low unburned carbon in ash 3. Low SOX with direct desulphurization by adding limestone 4. Low NOX with controlled temperature and air staging)

High operational reliability, and long life

Minimised operation and low cost and footprints

Low ash carbon content, can be reused

Expert firing system with high efficiency cyclone

Provide real, tangible improvements for your investment.

■ Founded in 1956, a quality supplier assessed, certified and inspected by SGS Group

■ CE ASME DOSH EAC GOST TUV BUV ISO boiler certificates

■ More than 17 years of export experience, gold medal supplier, payment and delivery guaranteed

■ Integrating research&development production and sales

■ Support video/VR or third party factory inspection

■ Best seller in 108 countries, more than 100,000 customers

Quality Control

Boiler Service

Pre-sale Service:

1. Design一We help customer to choose the best boiler model according to the different requirements of different industries.

2. Drawing and files一Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution一Design completed boiler solution with installation materials for your company.

4. Competitive Price一As one boiler factory, we have lowest price and high quality.

After-sale Service:

1. Provide a full range of boiler and original spare parts.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.

Parameter

| Model | Rated Steam Capacity | RatedSteamPressure | RatedSeamTemperature | FeedWaterTemperature |

| Unit | t/h | Mpa | (℃) | (℃) |

| SHX4-1.25-AII | 4 | 1.25 | 194 | 105 |

| SHX6-1.25-AII | 6 | 1.25 | 194 | 105 |

| SHX8-1.25-AII | 8 | 1.25 | 194 | 105 |

| SHX8-1.6-AII | 10 | 1.6 | 204 | 105 |

| SHX10-1.25-AII | 10 | 1.25 | 194 | 105 |

| SHX10-1.6-AII | 10 | 1.6 | 204 | 105 |

| SHX10-2.5/400-AII | 10 | 2.5 | 226 | 105 |

| SHX12-2.5.WI | 12 | 2.5 | 226 | 105 |

| SHX15-1.25-AII | 15 | 1.25 | 194 | 105 |

| SHX15-1.6-AII | 15 | 1.6 | 204 | 105 |

| SHX15-2.5-AII | 15 | 2.5 | 226 | 105 |

| SHX20-1.25-AII | 20 | 1.25 | 194 | 105 |

| SHX20-1.6-AII | 20 | 1.6 | 204 | 105 |

| SHX20-2.5-AII | 20 | 2.5 | 226 | 105 |

| SHX20-2.5/400-AII | 20 | 2.5 | 226 | 105 |

| SHX25-1.25-AII | 25 | 1.25 | 194 | 105 |

| SHX25-1.6-AII | 25 | 1.6 | 204 | 105 |

| SHX25-2.5-AII | 25 | 2.5 | 226 | 105 |

| SHX25-2.5/400-AII | 25 | 2.5 | 226 | 105 |

| SHX30-1.25-H | 30 | 1.25 | 194 | 105 |

| SHX30-1.6-WI | 30 | 1.6 | 204 | 105 |

| SHX35-1.25-AII | 35 | 1.25 | 194 | 105 |

| SHX35-1.6-AII | 35 | 1.6 | 204 | 105 |

| SHX35-2.5-AII | 35 | 2.5 | 226 | 105 |

| SHX35-2.5/400-AII | 35 | 2.5 | 226 | 105 |

| SHX40-1.6-AII | 40 | 1.6 | 204 | 105 |

| SHX45-1.6-AII | 45 | 1.6 | 204 | 105 |

| SHX50-1.6-A1 | 50 | 1.6 | 204 | 105 |

| SHX65-1.6-AII | 65 | 1.6 | 204 | 105 |

| SHX75-1.6-AII | 75 | 1.6 | 204 | 105 |

| SHX75-2.5/400-AII | 75 | 2.5 | 226 | 105 |

| YD-20/3.82-M | 20 | 3.82 | 450 | 105 |

| YD-25/3.82-M | 25 | 3.82 | 450 | 105 |

| YD-35/3.82-M | 35 | 3.82 | 450 | 105 |

| YD-40/3.82-M | 40 | 3.82 | 450 | 105 |

| YD-50/3.82.M | 50 | 3.82 | 450 | 105 |

| YD-65/3.82-M | 65 | 3.82 | 450 | 105 |

| YD-65/5.29-M | 65 | 5.29 | 485 | 105 |

| YD-75/3.82-M | 75 | 3.82 | 450 | 105 |

| Nole: The design of the abowe boler model fuel is ony one of a variely of uels, eoch ype of boler can be proided in accordance wih he fuel provided by the custome. | ||||

| Model | Rated Heating Capacity | Pressure | Rated Outlet Temperature | FeedWaterTemperature |

| Unit | MW | Mpa | (℃) | (℃) |

| QXX7-1.0/95/70-AI1 | 7 | 1 | 95 | 70 |

| QXX10.5-1.25/115/70-AI | 10.5 | 1.25 | 115 | 70 |

| QXX14-1.25/95/70-A11 | 14 | 1.25 | 95 | 70 |

| QXX14-1.0/115/70-H | 14 | 1 | 115 | 70 |

| QXX14-1.25/115/70-H | 14 | 1.25 | 115 | 70 |

| QxX17.5-1.25/115/70-H | 17.5 | 1.25 | 115 | 70 |

| QXX17.5-1.25/130/70-H | 17.5 | 1.25 | 130 | 70 |

| QXX29-1.25/130/70-H | 29 | 1.25 | 130 | 70 |

| QXX29-1.6/150/90-H | 29 | 1.6 | 150 | 70 |

| QXX36-1.25/130/70-AI | 36 | 1.25 | 130 | 70 |

| QXX36-1.6/130/70-AI | 36 | 1.6 | 130 | 70 |

| QXX46-1.25/130/70-H | 46 | 1.25 | 130 | 70 |

| QXX46-1.6/130/70-H | 46 | 1.6 | 130 | 70 |

| QXX58-1.25/130/70-H | 58 | 1.25 | 130 | 70 |

| QXX58-1.6/130/70-H | 58 | 1.6 | 130 | 70 |

| QXX64-1.25/130/70-H | 64 | 1.25 | 130 | 70 |

| QXX64-1.6/150/90-H | 64 | 1.6 | 150 | 70 |

| Nole: The design of the abowe boler model fuel is ony one of a variely of uels, eoch ype of boler can be proided in accordance wih he fuel provided by the custome. | ||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler