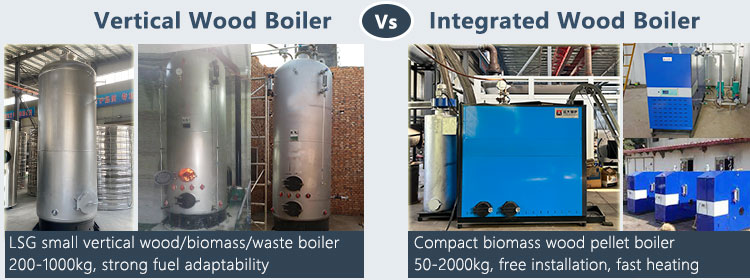

Manual type wood boiler | Automatic wood boiler | Vertical wood boiler

DZH series wood boiler, also known as hand-feeding boiler, economical boiler, which needs labour to feed fuel and remove the slag. Specially designed boiler for small capacity below 8 tons/hour.

| Output: | steam, hot water |

| Capacity: | 100kg-50000kg, 0.1ton-50ton, 120kw-28000kw |

| Work Pressure: | 3-40bar, 0.3-4.0Mpa |

| Heat Temperature: | 0-450℃ |

| Applied Industry: | For heating/drying/turbine drive, in food, beverage, paper plant, textile mill, feed mill, pharm, package, chemical, building materials, laundry etc |

Introduction

Yuanda providing one-stop wood boiler solution, produce steam or hot water for factory production, or turbine drive.

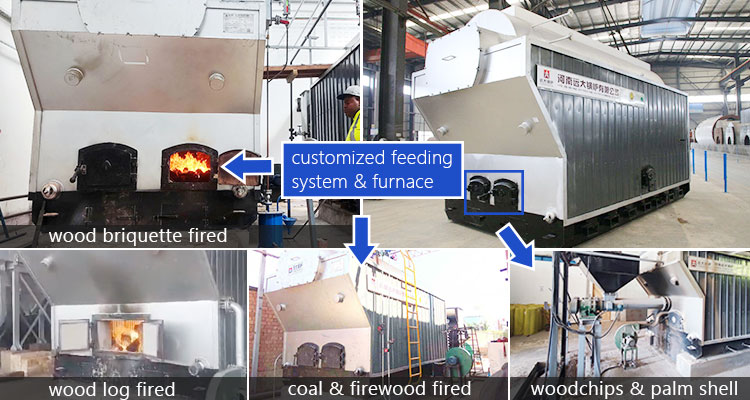

Fuel can be firewood, logs, briquette, wood block, or irregular size wood residues, wood chips, wood pellet, sawdust and high himidity wood waste etc.

● DZH wood boiler, using fixed grate, also known as manual type boiler, economical boiler, which needs labour to feed fuel and remove the slag.

It has limited capacity due to labor feeding, max 8ton/h.

● DZL SZL automatic wood boiler, using moving grate like chain grate or reciprocating grate(step grate), automatic feeding and slag remove, energy saving boiler with high efficiency.

It can provide greater steam/water output capacity, max 50ton/h.

1. Adopts 3-pass wet back sturcture, arched tube plate, spiral corrugated fire tubes, to strengthen boiler efficiency, prevent tube plate cracking

2. Two-Wing flue gas at side, reduce smoke temperature, reduce heat load of boiler bottom and prevent bulge.

3. Secondary air ventilation system in boiler, increase burning efficiency and save fuel cost

4. Built-in steam separator, ensure high steam quality with wetness below 1%

5. Anti-dry heating system, five stages water level check, four stages pressure protection

6. Built-in rotary sootblower and inspection door

7. New large furnace design with dust separation chamber, make boiler high efficiency, reduce the original dust

Pre-sale Service:

1. Design一We help customer to choose the best boiler model according to the different requirements of different industries.

2. Drawing and files一Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution一Design completed boiler solution with installation materials for your company.

4. Competitive Price一As one boiler factory, we have lowest price and high quality.

After-sale Service:

1. Provide a full range of boiler and original spare parts.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.

Quality Assurance

Steel element test→Steel rust cleaning→Welding electrodes drying process→Automatic welding, argon arc welding, expansion welding etc. methods→NDT(Nondestructive Testing) including X-ray Test, Ultrasonic Test, Magnetic particle Test→Hydraulic pressure test.

FAQ of DZH Boiler

1. How much fuel does the boiler use per hour?

Take 1 ton firewood steam boiler as an example, the consumption is 140kg/h.

2. Worried about the installation?

Except installation manual, also we can send engineers to install boiler.

3. Can wast jute or coal be burned in a DZH boiler?

Yes. DZH boiler has wide fuel adaptability, can burn all most solid fuel.

4. Can high moisture fuel be burned in DZH boiler?

No. We have special designed reciprocating grate boiler for high moisture fuel.

Parameter

| Model |

Rated steam output (Ton/hr) |

Rated steam pressure (Mpa) |

Rated steam temperature (℃) |

Feed water temperature (℃) |

Thermal efficiency(%) | Fuel consumption(Kg/h) |

| DZH 1 | 1 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 140 |

| DZH 2 | 2 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 280 |

| DZH 4 | 4 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 570 |

| DZH 6 | 6 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 810 |

| DZH 8 | 8 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 1100 |

| DZL 10 | 10 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0/3.82 | 130~304 | 20/105 | >84 | 1380 |

| DZL 15 | 15 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0/3.82 | 130~304 | 20/105 | >84 | 2100 |

| DZL 20 | 20 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0/3.82 | 130~304 | 20/105 | >84 | 2600 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Products Series

Contact Supplier