hot air biomass furnace| hot air coal furnace | woodchip hot air generator

Yuanda Boiler hot air furnce is a quick-assembled hot air generator designed for versatile industrial heating applications. It features both an upper heat exchanger and a lower traveling chain grate combustion chamber, could burning coal, wood chip and biomass fuel well.

| Output: | hot air |

| Capacity Range: | 300.000kcal to 4800.000kcal |

| Horsepower | 20hp to 550hp |

| Working Temperature | <400℃ |

| Applied Industries: | heating or drying purpose in food, chemical, casting, textile, motorcycle, wood products etc |

Introduction

Hot air furnace is a kind of equipment which makes use of coal/biomass fuel to heat air and produce hot air. Yuanda Boiler hot air furnace is a quick-assembled hot air generator designed for versatile industrial heating applications.

It features both an upper heat exchanger and a lower traveling chain grate combustion chamber, could burning coal, wood chip and biomass fuel well.

Low energy consumption, high thermal efficiency, automatic temperature measurement and display. Its thermal output ability ranges from 200.000kcal to 12.000.000kcal and it can provides 20-800℃ hot air. And we can customize based on real needs.

A. High thermal efficiency ≥85℅;

B. Better for environmental protection; no harm produced;

C. Temperature rises quickly, it only takes 20 minutes from heating, rising and normally running.

D. High automation level, air temperature can be adjusted freely in a certain range.

E. Stable hot air, the temperature control accuracy can be maintain at about 5 degree centigrade;

F. Safe and reliable, complete devices to guarantee safety.

G.The furnace employs advanced multiple spiral groove plate heat exchange technology alongside turbulent flow principles.

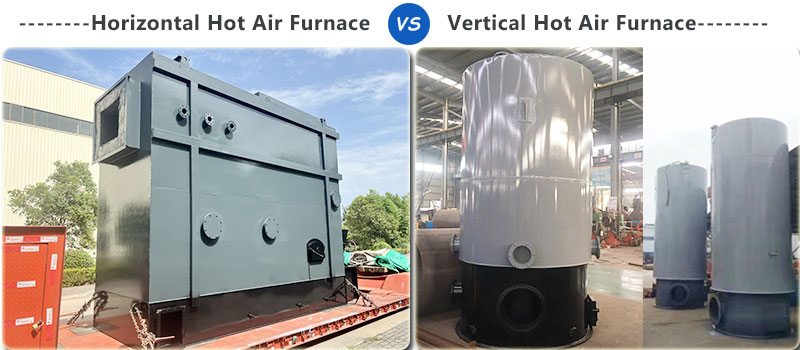

Based on heating methods, hot air generator can be classified into 2 types:

Direct Hot Air Boiler: This variant operates without a heat exchanger, with the flue gas from combusted fuel directly warming the air. Suitable for lower standards of hot air cleanliness, like cement, sand, briquettes, sludge, Etc.

Indirect Hot Air Boiler: This type incorporates a heat exchanger to generate clean heated air, suitable for milk powder, pharmaceuticals, synthetic resins, fine chemicals, and similar products.

1. Processing drying of chemical products and medicines.

2. Baking coatings and powder spraying curing in the car, motorcycle, container, household appliances, etc., field.

3. Textile printing and garment field for the thermoforming, thermosol dyeing, baking and hot air stenter, etc.

4. Casting industry moulding sand and sand core drying.

5. Building materials industry, wood drying, man-made board, laminated sheet drying, drywall drying, glass fiber products drying.

6. Roasting for agricultural products, feed and food processing.

7. Heating industrial plants and civil buildings.

8. Welding industry and solder drying.

9. Drying in heat preservation material, glass fiber reinforced plastic industry, aluminium silicate products, rare earth heat preservation, glass reinforced plastic products, etc., field.

■ Founded in 1956, a quality supplier assessed, certified and inspected by SGS Group

■ CE ASME DOSH EAC GOST TUV BUV ISO boiler certificates

■ More than 17 years of export experience, gold medal supplier, payment and delivery guaranteed

■ Integrating research&development production and sales

■ Support video/VR or third party factory inspection

■ Best seller in 108 countries, more than 100,000 customers

Pre-sale Service:

1. Design一We help customer to choose the best boiler model according to the different requirements of different industries.

2. Drawing and files一Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution一Design completed boiler solution with installation materials for your company.

4. Competitive Price一As one boiler factory, we have lowest price and high quality.

After-sale Service:

1. Provide a full range of boiler and original spare parts.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.

Quality Assurance

FAQ of YDHT Boiler

1. What fuel can be burned out?

Wide fuel adoptable: coal , wood chip, wood log, saw dust and so on

2. Worried about the installation?

①We have skid mounted boiler, free of installation; ②We can send engineers to install boiler.

3. Don't have enough space in our factory?

We have vertical hot air furnace boiler, small footprint.

4. Do you have agent here?

No. We prefer factory direct to have lowest price and quality assurance.

Parameter

| Model |

Steam output (Ton per hour) |

Rated steam pressure (Mpa) |

Rated steam temperature (℃) |

Feed water temperature (℃) |

Thermal efficiency (%) |

Fuel consumption (Kg/h) |

| DZL 1 | 1 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >84 | 150 |

| DZL 2 | 2 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >84 | 280 |

| DZL 4 | 4 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >84 | 570 |

| DZL 6 | 6 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >84 | 810 |

| DZL 8 | 8 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >84 | 1100 |

| DZL 10 | 10 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >84 | 1380 |

| DZL 15 | 15 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >84 | 2100 |

| DZL 20 | 20 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >84 | 2600 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Products Series

Contact Supplier